The three ways that risers should be designed for cast iron are explained along with the factors that affect volume change. Namely the gating and Risering systems.

Pdf Design Optimization Of Gating System By Fluid Flow And Solidification Simulation For Front Axle Housing Semantic Scholar

Gating system with sprocket.

. The gating system is composed of. Gating and riser system are designed with the help of mathematical formulae. Design for expendable-mold casting Riser design.

GATING AND RISERING Rajesh. A C programme has been developed to calculate the areas of sprue. So in simulation that we prepared gating system.

Gating and Risering Basics introduces the learner to the various components of the filling and feeding systems as well as their role and design in transporting the molten metal into the casting cavityThis knowledge is foundational for designing the gating and risering systems for efficiently filling of the mold cavity to produce quality castings. S MTech Assistant Professor Department of mechanical Engineering Vemana Institute of Technology Bangalore 2. Gating and risering system design Written By rossman Thursday March 17 2022 Add Comment Edit.

Casting quality is heavily dependent on the success of gatingriser system design which currently is conducted mainly relied on technicians experience. Predict velocity and pressure of the molten metal in the gating system. Here we have designed a gating system for given component.

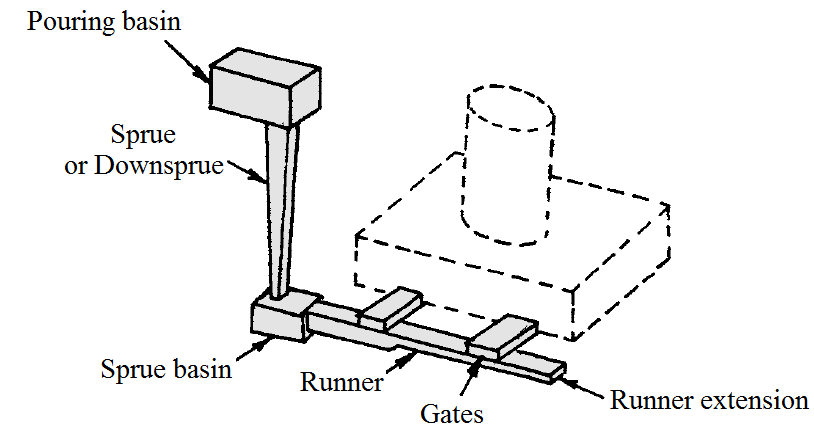

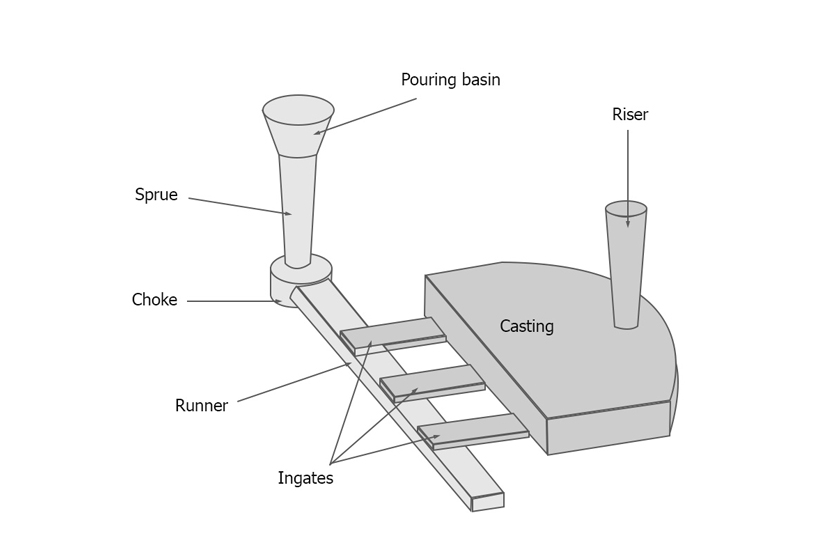

On the success of gatingriser system design which is currently conducted mainly relying on the technicians experience. If the riser is located on the casting then it is known as a top riser but if it is located next to the casting it is known as a side riserTop risers are advantageous because they take up. Gating Risering System Gating system is to lead clean molten metal poured from ladle to the casting cavity with less turbulence.

DESIGN OF DOWN-RUNNER OR SPRUE 21 Calculate the weight of liquid metal to be poured includes the casting the feeder and all elements of gating system 22 Choose location and design of gating system. Risers have been designed and placed such that the whole casting is free from shrinkage. The Gating and Risering System The Rigging System Customer Requirements.

Pouring basin-It is the conical hollow element or tapered hollow vertical portion of the gating system which helps to feed the molten metal initially through the path of gating system to mold cavity. Identify the effects of process parameters on gating system design. May 16th 2019 - Sand Casting Product Is The Gating System Design And Risering System Design 3 4 Any Improper Designing Of Gating System And Risering System Results In Cold Shut And Shrinkage Porosities Therefore Adequate Care Is Necessary In Designing Gating And Risering Systems For Improved Yield Of Defect Free Castings.

Blind risers are good design features and maintain heat longer than open risers. CONCEPT OF GATING AND RISERING DEFINTION TYPES OF GATES GATING DESIGN GATING RATIO RISERING TYPES FUNCTIONS 3. It may be made out of core sand or it may be cut in cope portion of.

Definition and functions of the riser. Different types of gates. Determine gate sizes and locations.

Describe the basics of fluid dynamic principles. Types of risers and their application. One of the main variables that should be considered when designing a gating system is the flow of molten metal while filling the mould.

Risers are used to compensate for liquid shrinkage and solidification shrinkage11 1No shrinkage defects. Therefore there is a need for the development of a computer-aided casting process design tool with CAD simulation and optimization functions to ensure the quality of casting. 25 CAD model with gating system.

This module identifies the uniqueness of feeding graphitic cast iron alloys. Quality of the casting. Design gating and risering system design mold design pouring of molten metal each process has its own effects on.

Design of the riser - its shape. As per the results of e-foundry we found out that our gating system must eliminate hotspots from teeth and central position that are remaining hot at the end. Gating ratio and its functions.

The success of a sand casting process depends mainly on the design of efficient mold rigging systems. 23 Determinedecide on total. Course Length 20 days CEU Units 120 CEU Course outline.

Components of the gating System and its functions. Namely the Gating and Risering systems. By the end of this module you will be able to list unique riser considerations for iron castings.

Bad design of the gating and feeding system can result in defects in the castings. However it is observed that the mold preparation in most of local foundries in Palestine depends totally on the experience of the foundry man who does not pay much attention to the engineering mold. Design of the gating system.

Risers size and location are extremely useful in affecting-front progression across a casting and are essential feature in the mold layout. Module 5 - Principles of Gating and Risering Purpose of the gating system. A riser is categorized based on three criteria.

ELEMENTS OF GATING SYSTEM 1Pouring basin 4. PDF The success of a sand casting process depends mainly on the design of efficient mold rigging systems. Though we have a number of scientific approaches to the design of the gating and risering most foundries still prefer to have the traditional way of designing gating feeding systems by trials and experimentations.

The flow of molten metal in mold accounts for almost 60 of the casting defects and due to this. Designing a gating system in a purely scientific way demands through knowledge in the thermal and fluid dynamics field.

Types Of Gating System In Casting Process Bajrang Engineering

Pdf Automation Of Gating System Parameters For Green Sand Iron Castings

Riser And Gating Design Engineers Knowledge

Pdf Optimized Design Of Gating Riser System In Casting Based On Cad And Simulation Technology Semantic Scholar

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Ductile Iron The Essentials Of Gating And Risering Sorelmetal

Gating System For Casting Excellent Animation Youtube

Gating System Top Gate Bottom Gate Parting Line Gate Youtube

0 comments

Post a Comment